Cable tie mounts allow for the smooth movement of cables, cable bundles, and tubes. The wires or tube can be fixed and simply pushed along by inserting a cable tie via the mount and securing it to the cables or tube.

After you have successfully attached the mount, you will then weave a cable tie between the holes. Put the tube, cable, or cable bundle in the appropriate location on the mount, and then use the cable tie to keep it in place there.

Application of tie mounts

Fasteners called cable ties are used to connect wires and cables. They are also known as wire ties, hose ties, zip ties, and tie wraps. Cable tie mounts have a pawl or head at one end and sharp teeth on the other. A lock that can’t be released is created by the teeth that are placed through the head.

Extra cable ties can be cut off after the appropriate loop size has been attained for bundling all of the wires and cables together. They offer the most efficient method of maintaining wires and cables in an ordered, damage-free state. Based on the needs of the application, they are available in a variety of temperature ranges, materials, mechanical and tensile strengths, lengths and widths, and colours.

Application to aircraft

In aircraft, Cable tie mounts are frequently utilized. Electrical wiring and cables are necessary components of an airplane for the safe operation of the entire system. When electrical issues emerge, keeping these wire bundles tidy makes airplane repairs simple.

In an aircraft, many kinds of cable ties are required. They must adhere to the requirements of components and parts for the function they will perform. In general, heat-stabilized conventional, push mounting, and heavy-duty zip ties are the best types of cable ties to use in aeronautical applications.

Application to automotive

For usage in automotive applications, Cable tie mounts have to be heat resistant as well as chemicals. They ought to be able to endure being exposed to hostile conditions, oil, grease, and gasoline.

Due to their extreme corrosion, hot temperatures, and resistance to abrasion, stainless steel cable connections are frequently utilized to meet these specifications. In addition to regular cable ties, push mounts, and adhesive, arrowhead cable ties are another type of cable tie that is used in a variety of automotive applications.

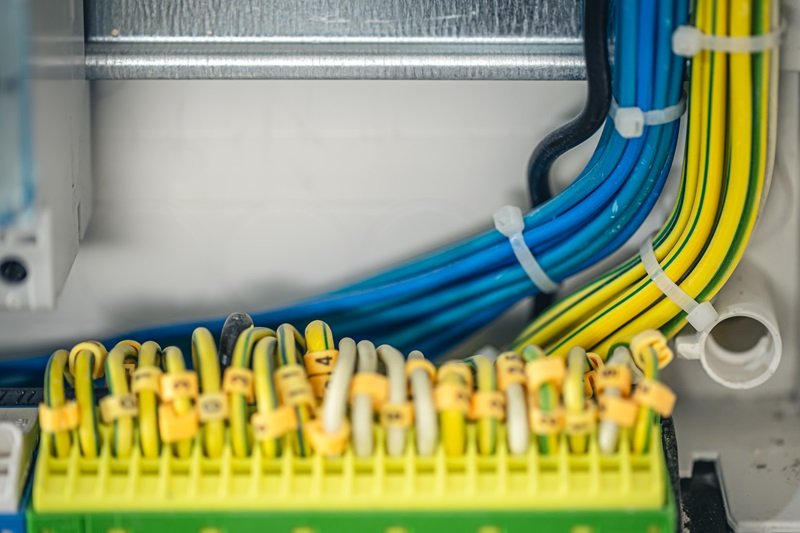

Application to Utility Enclosures

Utility enclosures, both interior and exterior, are prone to messy cable and wire configurations. To hold and organize these cables and wires properly, combine regular cable ties in various colours and marker cable ties containing tags connected for recognition. Heavy-duty situations can also make use of stainless-steel cable ties.

Application to Manufacturing

During operation, industrial machinery and other components frequently vibrate. Fir tree Cable tie mounts can guard against debris entry and stop rattling in high-vibration applications. Screw-mount cable ties are advised for indoor application. In such case, you’ll need cable ties that can withstand heat and are impervious to the elements.

Application to Appliances and Consumer Electronics

Wire bundles for various gadgets and appliances can be made using arrowhead or heat-stabilized Cable tie mounts. By minimizing potential risks brought on by tangled connections, they provide an ordered and secure workplace.

Types of tie mounts

Aside from cable tie wall plugs, there are two different kinds of cable tie mounts:

- Self-adhesive cable tie mounts

- Saddle tie mounts with screw mount

The same purpose is served by both of these varieties of mounts: routing cable or tubes across a wall.

Polyamide 6.6 is the material used to make various self-adhesive cable tie mounts as well as saddle tie mounts incorporating screw mounts.

The only significant difference between these two mounts with screws is that self-adhesive cable tie mounts contain an adhesive band that can be applied to connect the mount to a surface. Within each of the saddle tie mounts, there is a drilled hole. The drill hole in the mount can be used to attach it to a wall or even another surface with a screw.

Conclusion

One can purchase the precise cable tie mounts they need for their project because there are many different stock options available. Some of them are designed to be installed outside and require a high tensile strength to meet the criteria. The majority are unaffected by salt, oil, and grease, which are all common types of air contaminants.