Introduction

When it comes to mesh construction, MS expanded metal is rapidly gaining popularity. Its versatility, strength, and cost-effectiveness make it a top choice for many industries, from architecture to security. In this post, we’ll explore how is changing the landscape of mesh solutions and why it’s a game-changer in the construction industry.

Whether you’re in construction, design, or manufacturing, understanding the advantages of can help you make more informed decisions about your next mesh project. Let’s dive into why MS is revolutionizing mesh construction.

What is MS Expanded Metal?

Before diving into its benefits, let’s first understand what MS expanded metales is and how it differs from other types of mesh products.

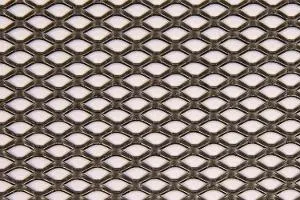

- Definition: MS (Mild Steel) expanded metales is a metal sheet that has been slit and stretched to form a mesh pattern with diamond-shaped openings. This process creates a lightweight yet durable material that is both flexible and strong.

- Manufacturing Process: The sheet metal is cut using specialized tools and then expanded (stretched) to create uniform apertures. Unlike perforated metal, which is punched, MS expanded metal maintains the integrity of the metal sheet by not losing any material during the expansion.

- Types of Expanded Metal:

- Standard Expanded Metal: The traditional, rigid mesh with uniform diamond-shaped openings.

- Flattened Expanded Metal: The sheet is compressed after expansion, making it smoother and easier to work with.

Key Benefits of MS Expanded Metal in Mesh Construction

MS expanded metales stands out because of its unique blend of strength, versatility, and cost-effectiveness. Let’s look at the key benefits:

1. Increased Strength and Durability

MS expanded metales is incredibly strong for its weight, which makes it ideal for demanding applications in construction and manufacturing.

- High Strength-to-Weight Ratio: The expansion process creates a structure that maintains high strength while using less material. This results in lighter, more cost-effective mesh.

- Longevity: MS expanded metal is durable and resistant to wear, corrosion, and environmental elements, which makes it a long-lasting solution for outdoor and industrial uses.

2. Cost-Effectiveness

Compared to other mesh solutions like welded wire mesh or perforated metal, MS expanded metal is often more affordable.

- Material Efficiency: Since the metal is expanded without any material waste, it maximizes the use of raw materials.

- Lower Manufacturing Costs: The process of creating MS expanded metal requires fewer resources than traditional methods, reducing production costs.

- Reduction in Transport Costs: Because MS expanded metal is lighter than solid metal sheets, it reduces shipping costs, offering a more budget-friendly option for large projects.

3. Versatility in Applications

MS expanded metal can be customized for various uses, offering a wide range of mesh designs.

- Architectural Design: From facades to sunshades, MS expanded metal adds a modern touch to architectural projects, creating striking visual effects while maintaining functionality.

- Industrial Applications: Its strength makes it an excellent choice for industrial fencing, walkways, platforms, and security barriers.

- Customizable Apertures and Thicknesses: The expanded metal pattern can be altered to meet specific design or strength requirements, making it ideal for diverse applications.

MS Expanded Metal’s Role in Revolutionizing Mesh Solutions

MS expanded metal is not just a material—it’s changing the way industries approach mesh construction. Here’s how it’s revolutionizing mesh solutions:

1. Improved Design Flexibility

MS expanded metal offers unmatched design flexibility. Whether you need a finer pattern for decorative purposes or a more open design for ventilation, MS expanded metal can be tailored to fit your needs.

- Customizable Aperture Size: The size of the openings can be adjusted to accommodate different requirements, such as airflow or load-bearing capacity.

- Pattern Variety: MS expanded metal can be produced in a range of patterns and configurations, allowing for creative and functional designs in a variety of sectors.

2. Sustainability and Eco-Friendliness

In today’s world, sustainability is key. MS expanded metal is an environmentally friendly solution that aligns with modern construction goals.

- Minimal Material Waste: The manufacturing process involves minimal waste compared to perforated metal or welded wire mesh.

- Recyclability: Like many other metal products, MS expanded metal is fully recyclable, reducing its environmental impact.

- Energy Efficiency: By using less raw material and creating a more efficient design, MS expanded metal contributes to energy savings in both production and use.

Key Applications of MS Expanded Metales in Construction and Industry

MS expanded metal’s strength, cost-effectiveness, and versatility make it ideal for numerous industries. Let’s explore some key applications:

1. Construction Industry

MS expanded metal is used in various construction applications due to its strength and durability.

- Reinforcement and Support: Used in structural reinforcement, MS expanded metal adds support to concrete structures, enhancing strength without adding much weight.

- Safety Barriers: It’s used for making protective barriers and fencing for construction sites, offering a cost-effective solution for site safety.

2. Architectural and Design

MS expanded metal’s visual appeal makes it a popular choice for modern architecture and design.

- Decorative Facades: Its unique patterns are used in building facades, providing both aesthetic value and functionality (e.g., sunlight control, ventilation).

- Sunshades and Screens: MS expanded metal is used for shading systems that help regulate temperature and light flow in buildings, enhancing energy efficiency.

3. Security and Safety

MS expanded metal is commonly used in security and safety products due to its robust design.

- Fencing and Gates: It provides security for commercial, residential, and industrial sites.

- Walkways and Platforms: MS expanded metal is often used for creating safe walkways, platforms, and grating systems in industrial facilities.

4. Automotive and Aerospace

MS expanded metal is lightweight and durable, making it ideal for use in automotive and aerospace industries.

- Automotive Grills and Components: Its strength-to-weight ratio makes it perfect for use in parts like grilles and protective covers.

- Aerospace Applications: MS expanded metal’s lightweight and durable nature makes it an excellent choice for structural components in the aerospace sector .

MS Expanded Metal vs. Traditional Mesh Solutions

MS expanded metales offers several advantages over traditional mesh solutions, such as welded wire mesh and perforated metal.

Comparison to Welded Wire Mesh:

- Welded wire mesh often has thicker wires and requires more material, making it heavier and more expensive than MS expanded metal.

- MS expanded metal offers better flexibility and customization options.

Comparison to Perforated Metal:

- Perforated metal is produced by punching holes in solid metal sheets, which results in more material waste compared to the expansion process used for MS expanded metal.

- MS expanded metal retains the strength of the original sheet, making it more durable and cost-effective.

How to Choose the Right MS Expanded Metal for Your Project

When selecting MS expanded metales, there are a few key factors to consider:

- Material Type: Choose the right metal for your project, whether it’s mild steel, stainless steel, or another alloy, depending on the environmental conditions and strength requirements.

- Aperture Size: Consider the size of the openings in the mesh, as this will affect the material’s functionality and appearance.

- Thickness: The thickness of the sheet will impact the mesh’s strength and durability, so choose the appropriate thickness based on your specific needs.

- Pattern and Shape: Decide on the pattern of the mesh based on both aesthetic and functional requirements, such as ventilation, privacy, or strength.

Conclusion

MS expanded metal is revolutionizing mesh construction by offering superior strength, cost-efficiency, and design flexibility. Its ability to be customized for a wide range of applications makes it an ideal choice for industries like construction, security, and design. With its eco-friendly manufacturing process and sustainability, MS expanded metal is paving the way for more efficient and innovative mesh solutions.

If you’re considering a mesh solution for your next project, MS expanded metales could be the perfect choice. Whether you’re building, designing, or securing, MS expanded metal offers the strength, flexibility, and cost-effectiveness you need to take your project to the next level.