Selecting the right globe valve manufacturers is crucial for ensuring the efficiency, safety, and reliability of your fluid control systems. This comprehensive guide will help you navigate the process of identifying and choosing reliable manufacturers that meet your industry-specific needs.

Understanding Globe Valves

Definition and Function

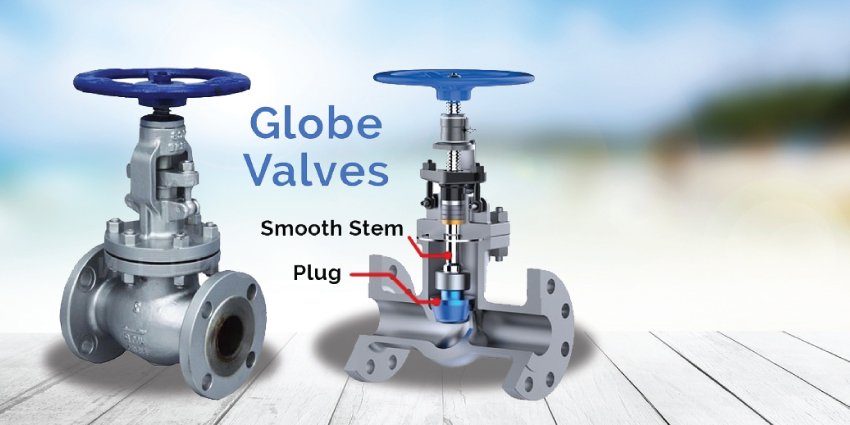

Globe valves are a type of valve used to regulate the flow of fluids in a pipeline. Their design allows for precise control over the flow rate, making them ideal for applications where throttling is required. Globe valves are commonly used in industries such as oil and gas, water treatment, and chemical processing.

Key Features of Globe Valves

Flow Regulation: Globe valves offer excellent control over fluid flow, making them suitable for throttling applications.

Durability and Construction Materials: Typically made from robust materials like stainless steel, cast iron, or brass, globe valves are designed to withstand harsh operating conditions.

Design Variations: Common designs include Z-type, Y-type, and angle type, each suited to specific applications.

Importance of Selecting Reliable Manufacturers

Quality Assurance

Reliable manufacturers ensure high standards in their manufacturing processes, which is critical for producing durable and efficient globe valves. Quality control measures help prevent defects and ensure that each valve meets the required specifications.

Operational Efficiency

Using globe valves from reputable manufacturers can significantly enhance the efficiency of your fluid control systems. High-quality valves reduce the risk of leaks and failures, leading to lower maintenance costs and less downtime.

Safety and Compliance

Ensuring that the globe valves comply with industry standards and regulations is essential for safe operation. Reliable manufacturers adhere to these standards, providing peace of mind that their products are safe and effective.

Criteria for Selecting Reliable Globe Valve Manufacturers

Industry Experience and Reputation

Evaluate Manufacturer’s History: Look for manufacturers with a long-standing presence in the industry. Experience often correlates with expertise and reliability.

Customer Reviews and Reputation: Check customer reviews and testimonials to gauge the manufacturer’s reputation. Positive feedback from other companies in your industry can be a good indicator of reliability.

Product Range and Customization

Variety of Globe Valves: A reliable manufacturer should offer a wide range of globe valves, including different types, sizes, and materials.

Customization Capabilities: Some applications may require custom solutions. Choose manufacturers who can provide tailored valves to meet your specific needs.

Certifications and Standards

ISO Certifications: Ensure the manufacturer holds relevant ISO certifications, which indicate adherence to international quality standards.

Industry-Specific Standards: Look for compliance with industry-specific standards such as ASME and API. These certifications ensure that the valves meet the rigorous requirements of various industrial applications.

Manufacturing Capabilities

Advanced Technology: Manufacturers with state-of-the-art manufacturing facilities and technology are more likely to produce high-quality valves.

Quality Control Measures: Inquire about the manufacturer’s quality control processes. Rigorous testing and inspection procedures are essential for ensuring the reliability of the valves.

Technical Support and Service

Technical Support: Reliable manufacturers provide comprehensive technical support, including assistance with installation, operation, and troubleshooting.

After-Sales Service: Look for manufacturers who offer maintenance services, training, and warranty support. These services can be invaluable for ensuring the long-term performance of your valves.

Supply Chain and Delivery Reliability

Efficient Supply Chain Management: A well-managed supply chain ensures timely delivery of products, reducing the risk of project delays.

On-Time Delivery: Confirm that the manufacturer has a track record of delivering products on time. Reliability in delivery is crucial for maintaining project schedules.

Evaluating Potential Manufacturers

Conducting Market Research

Identify Potential Manufacturers: Use industry directories, online searches, and recommendations to compile a list of potential globe valve manufacturers.

Trade Shows and Industry Events: Attend trade shows and industry events to meet manufacturers and see their products firsthand.

Requesting and Reviewing Proposals

Detailed Proposals and Quotations: Request detailed proposals from shortlisted manufacturers. Compare product specifications, prices, and services to make an informed decision.

Comparing Options: Evaluate the proposals based on factors such as quality, price, and after-sales support.

Assessing Manufacturing Facilities

Plant Visits: If possible, visit the manufacturing facilities to assess their capabilities. A firsthand look can provide valuable insights into the manufacturer’s operations.

Quality Control Processes: Review the manufacturer’s quality control procedures and certifications to ensure they meet industry standards.

Checking References and Reviews

Contact Previous Clients: Ask for references from previous clients and contact them for feedback on their experience with the manufacturer.

Online Reviews and Testimonials: Read online reviews and testimonials to get a broader perspective on the manufacturer’s reputation.

Making the Final Decision

Comparing Options

Weigh Pros and Cons: Consider the advantages and disadvantages of each manufacturer. Look at factors such as product quality, price, delivery reliability, and after-sales support.

Long-Term Partnerships: Consider the potential for long-term partnerships. A reliable manufacturer can become a valuable partner in your operations.

Negotiating Terms and Conditions

Discuss Pricing and Delivery Schedules: Negotiate the terms of the contract, including pricing, delivery schedules, and warranties.

Finalize Agreements: Ensure that all agreements are clearly documented and signed by both parties.

Trial Orders and Performance Assessment

Place Initial Trial Orders: Start with a small order to evaluate the performance of the valves in real-world conditions.

Monitor Performance: Assess the valves’ performance over a period of time. Look for any issues and evaluate the manufacturer’s response to them.

Conclusion

Selecting reliable globe valve manufacturers is essential for ensuring the efficiency, safety, and reliability of your fluid control systems. By considering factors such as industry experience, product range, certifications, manufacturing capabilities, and technical support, you can make an informed decision that meets your industry-specific needs.