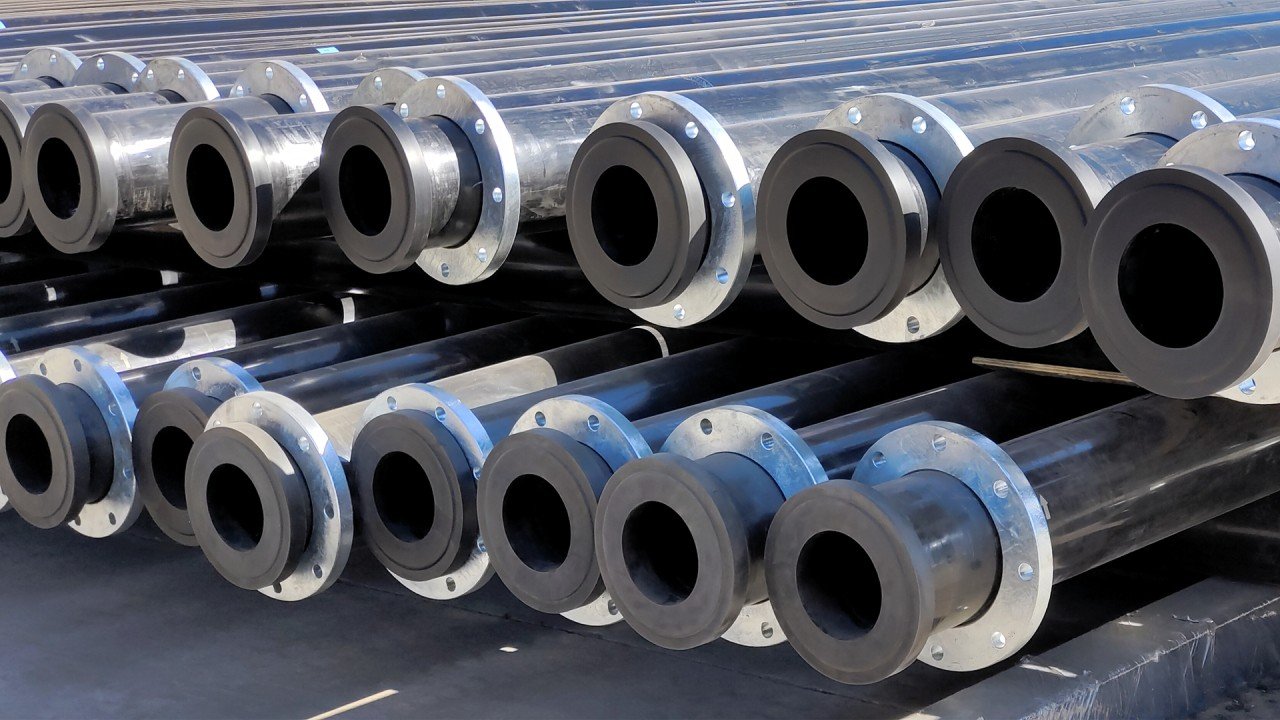

In the intricate world of mining operations, the choice of equipment and materials can heavily influence both the efficiency and safety of a project. Among these, mining pipes play a crucial role, impacting the success and longevity of mining projects. These pipes are essential in transporting fluids and materials, often in challenging conditions that demand high durability and resistance.

Mining operations face unique challenges, and the selection of high-quality pipes becomes critical to avoiding disruptions. Every component, including the mining pipes, must be chosen carefully to withstand extreme pressures and environmental conditions. An inappropriate choice can lead to costly interruptions, affecting productivity and safety.

Considering the complex requirements of mining projects, selecting the right type of mining pipes is more than a technical decision; it’s a strategic one. By ensuring the proper materials and designs, companies can significantly reduce risks and achieve long-term sustainability in their operations.

Durability and Sustainability of Mining Pipes

Durability is a cornerstone for any mining operation, and the choice of mining pipes directly affects the project’s lifespan. Mining sites are known for harsh conditions that require pipes to resist corrosion, wear, and constant pressure. Durable pipes minimize the frequency of replacements, reducing both costs and environmental impact.

Various materials, like steel, válvulas guilhotina and reinforced plastics, are common in mining pipes, each offering specific advantages. Steel pipes are renowned for their strength, while plastic options provide corrosion resistance and are often lighter and easier to handle. Each has trade-offs, but selecting the best fit depends on the specific demands of the mining environment.

Poor-quality pipes or materials unsuitable for mining can result in frequent repairs or replacements, which disrupt project schedules and lead to unplanned expenses. For a project to be sustainable, pipes must be able to endure the wear and tear of daily operations without compromising performance.

Investing in high-quality, durable mining pipes directly impacts long-term sustainability. By reducing the need for replacements, companies not only save on costs but also decrease their environmental footprint, aligning with more sustainable operational goals.

Efficiency in Material Transport and Flow

A seamless transport process is essential for productivity in mining, and the choice of mining pipes plays a pivotal role in ensuring an efficient flow of materials. Interruptions in this flow can lead to delays, which impact overall project timelines and increase operational costs.

Pipe diameter is a key factor in transportation efficiency. Larger pipes allow for more material to pass through, while smaller ones may create bottlenecks. Thus, the size and design of the pipe must match the volume and nature of the material being transported to maintain a smooth operation.

A well-chosen pipe system can enhance material flow, reducing the need for constant adjustments or interventions. This efficiency leads to increased output, maximizing the potential of the mining site and minimizing downtime due to maintenance or repairs.

Many successful mining projects have seen substantial improvements simply by optimizing their choice of mining pipes. When pipes are selected with attention to material flow, projects see enhanced efficiency, contributing to a smoother, more reliable mining operation.

Resistance to Harsh Conditions and Operational Safety

Mining environments expose equipment to extreme conditions, including high pressure, temperatures, and abrasive substances. For this reason, mining pipes must be designed to withstand these challenges without compromising safety.

Pipes exposed to these conditions require advanced materials that prevent corrosion and degradation, thereby minimizing the risk of leaks or bursts. Selecting pipes with strong resistance to wear and pressure is essential for maintaining safe operations, as failures in the pipe system could endanger personnel and equipment.

The right choice of mining pipes ensures safer conditions, protecting not only the infrastructure but also the workers. Safety regulations often demand the use of high-quality, durable pipes in such environments to minimize risks and comply with industry standards.

As mines adopt stricter safety protocols, the focus on selecting the correct mining pipes has increased. By choosing pipes that are designed to handle the specific challenges of a mining project, companies can create a safer work environment and reduce the likelihood of accidents.

Maintenance and Long-Term Cost Savings

Choosing the right mining pipes is a strategic decision that goes beyond initial costs, as it significantly impacts maintenance expenses and overall project economics. Investing in pipes that offer longevity and durability can reduce long-term expenditures associated with repairs and replacements.

Higher-quality pipes, though often more costly initially, require less frequent maintenance. This reduction in repair needs not only saves money but also minimizes operational downtime, allowing the project to proceed more smoothly and efficiently.

Materials that stand up to mining’s wear-and-tear requirements provide a clear cost benefit. They extend the period between necessary maintenance checks, enabling companies to optimize their budgets without sacrificing performance or reliability.

From a cost-benefit perspective, investing in durable mining pipes offers substantial financial advantages over time. Projects can maintain a steady operational flow, avoiding unexpected costs, and increasing overall profitability by reducing the frequency of replacements.

Expert Perspective on the Strategic Importance of Mining Pipes

Industry experts emphasize the importance of careful material selection for mining pipes. Heitor Gomes, CEO of Policon Control and Fluid Transportation, shares his insights: “The choice of mining pipes is vital, not only for the longevity of the project but for the safety and efficiency of operations. High-quality materials reduce the likelihood of disruptions and increase operational continuity.”

Gomes further notes that when companies overlook the quality of pipes, they often face greater expenses in the long run. “Companies can incur hidden costs when they prioritize initial savings over durability. A robust, well-designed pipe system is an investment that ultimately saves money and protects the workforce.”

His perspective reflects industry standards, highlighting the strategic advantage of choosing quality. In his view, making the right choice from the beginning avoids complications down the road, ensuring the operation remains both profitable and safe.

This expert insight underscores the tangible benefits of prioritizing quality and durability in mining pipes, a choice that goes beyond immediate cost to encompass safety and sustainability.

The Lasting Impact of Choosing the Right Mining Pipes

The choice of mining pipes can significantly influence the success and efficiency of a mining project. By selecting pipes that are durable and well-suited to the environment, companies can ensure smoother operations and reduce the likelihood of disruptions.

Long-term benefits include reduced maintenance costs, enhanced safety, and a more sustainable approach to mining. Choosing the right pipes of controle de fluidos enables a more reliable and efficient operation, which is essential in an industry where safety and productivity are paramount.

Ultimately, investing in high-quality mining pipes is a strategic decision that aligns with operational and environmental goals. Companies that prioritize durability, efficiency, and safety in their pipe selection set themselves up for long-term success, ensuring that their projects are not only effective but also sustainable and secure.