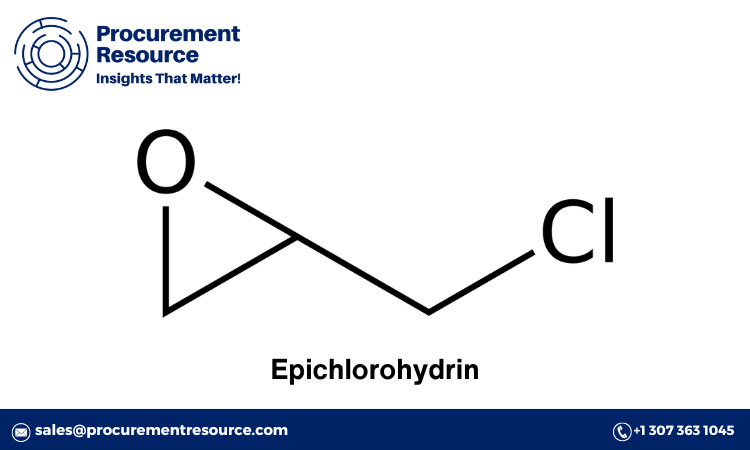

Epichlorohydrin (ECH) is a vital compound used in various industrial applications, including epoxy resin production, water treatment chemicals, and pharmaceuticals. Due to its wide-ranging applications, any fluctuation in the price forecast of epichlorohydrin can have a ripple effect across multiple industries, making accurate price forecasting essential for manufacturers and buyers alike. This report delves into current and future price trends for epichlorohydrin, examining key market dynamics, demand-supply factors, and other variables impacting its value.

2. Market Dynamics Impacting Epichlorohydrin Prices

a) Raw Material Costs

Epichlorohydrin is derived primarily from propylene, which is a petrochemical product. The price of propylene is heavily influenced by crude oil prices, which have been subject to global supply-demand shifts and geopolitical tensions. Additionally, propylene can be sourced from glycerin (a bio-based alternative), but the production volumes remain limited compared to petrochemical-based ECH. Thus, fluctuations in crude oil and glycerin prices directly impact Epichlorohydrin’s pricing.

Request For Sample: https://www.procurementresource.com/resource-center/epichlorohydrin-price-trends/pricerequest

b) Environmental Regulations

The production and handling of Epichlorohydrin involve health and environmental risks due to its toxic and carcinogenic properties. Regulatory bodies worldwide impose stringent standards on ECH production to minimize environmental and health impacts, affecting manufacturing costs. For instance, environmental policies in regions like North America and Europe may influence production capabilities and costs, leading to potential supply constraints that could push up prices.

c) Demand from Downstream Industries

The demand for epoxy resins is projected to grow due to expanding applications in electronics, automotive, construction, and renewable energy sectors. With the rise of electric vehicles, wind energy projects, and infrastructural developments, the need for durable and high-performance materials like epoxy resins is increasing. This growth in downstream demand for epoxy resins directly impacts ECH prices as manufacturers expand production to meet rising requirements.

3. Supply and Demand Analysis

a) Global Supply Chain Dynamics

Epichlorohydrin production is concentrated in a few major economies, including China, the United States, and parts of Europe. China has emerged as a prominent ECH producer, with its manufacturing capacity significantly influencing global prices. However, regulatory restrictions, periodic factory shutdowns, and environmental inspections can lead to supply disruptions, impacting global price levels.

Furthermore, with the adoption of sustainable practices, companies are increasingly turning to bio-based ECH production methods, although the transition is gradual and may not significantly impact supply until a later phase. The limited scalability of bio-based methods currently restricts the availability of ECH, creating potential upward pressure on prices.

b) Demand Trends

The demand for ECH is driven by its primary application in epoxy resins. With increasing industrialization in emerging markets and the expanding use of lightweight and durable materials in automotive and electronics, the demand for epoxy resins—and consequently ECH—is expected to rise. Moreover, the push for green energy and electric vehicles presents new growth avenues, as ECH-based products are integral in wind turbine blades, battery packs, and solar panels.

4. Extensive Forecast of Epichlorohydrin Prices

a) Short-Term Price Forecast

In the short term, Epichlorohydrin prices are anticipated to remain moderately volatile due to ongoing supply chain challenges and the potential for raw material price fluctuations. With global oil prices experiencing intermittent spikes, the cost of propylene (the primary raw material for ECH) is likely to influence ECH prices. Additionally, regulatory measures or environmental inspections affecting major ECH-producing countries may lead to temporary price hikes.

b) Medium to Long-Term Price Trends

In the medium to long term, Epichlorohydrin prices are projected to experience gradual growth, driven by:

- Increasing Demand: The global demand for epoxy resins is expected to grow, particularly in Asia-Pacific, due to industrial expansion and infrastructural projects. This will likely contribute to sustained demand for ECH, supporting price stability or gradual increases.

- Shift Towards Bio-Based Production: While bio-based Epichlorohydrin production is currently limited, advancements in sustainable practices may enhance bio-based ECH output, potentially moderating prices by diversifying supply sources.

- Technological Advancements: Technological innovations in ECH production processes may reduce costs, leading to stable or even slightly reduced prices in the long term if these methods are widely adopted.

5. Demand-Supply Analysis and Price Impact

A detailed examination of the demand-supply scenario reveals that Epichlorohydrin prices are likely to experience upward pressure in the near future, especially if raw material prices remain elevated. Key insights include:

- Supply Constraints: Regulatory measures and environmental restrictions in major producing countries could restrict supply, pushing prices higher.

- Strong Demand Growth: The rising use of epoxy resins in automotive, electronics, and construction indicates sustained demand for Epichlorohydrin.

- Regional Price Variability: Asia-Pacific is projected to lead demand growth, while North America and Europe may face relatively higher prices due to stricter environmental regulations affecting supply.

6. Detailed Insights and Future Outlook

The future of the Epichlorohydrin market appears robust, with steady demand growth anticipated across sectors. However, industry stakeholders must closely monitor the following factors:

- Regulatory Compliance and Cost: Compliance with environmental regulations will likely increase production costs for ECH manufacturers, impacting prices. Companies operating in regulated regions may need to invest in sustainable production methods to mitigate long-term cost pressures.

- Alternative Production Methods: The gradual adoption of bio-based Epichlorohydrin production could diversify the supply base, potentially stabilizing prices. While conventional production remains dominant, innovations in bio-based ECH production represent a promising alternative for the future.

- End-Use Demand Expansion: The growing electric vehicle, renewable energy, and construction markets will continue to drive demand for epoxy resins. As a result, ECH prices may trend upward to align with this demand expansion, especially in regions with high infrastructure and manufacturing growth.

The Epichlorohydrin price outlook suggests a complex interplay of factors influencing the market. While raw material costs and regulatory dynamics will shape short-term price fluctuations, rising demand from downstream industries and potential advancements in bio-based production may influence long-term trends.

For industry participants, a proactive approach in monitoring supply chain trends, regulatory changes, and end-user demand is essential for strategic planning. By staying informed about these factors, businesses can better navigate potential price fluctuations in the Epichlorohydrin market, ensuring effective procurement strategies and cost management in a competitive landscape.

Contact Us:

Company Name: Procurement Resource

Contact Person: Endru Smith

Email: sales@procurementresource.com

Toll-Free Number: USA & Canada - Phone no: +1 307 363 1045 | UK - Phone no: +44 7537171117 | Asia-Pacific (APAC) - Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA