Choosing the right membrane for a project on filtration is very important to delivering the right results especially when dealing with organizations that require high-grade filtration. Ultrafiltration membrane technology is employed in fields such as water purification, food production, and medicine because the effectiveness and efficiency of filtration in such processes are crucial. Among the available types of ultrafiltration membrane, the PVDF hollow fiber membrane is one of the most adored by industries because of its high-level performance. In this article, we will look at why PVDF hollow fiber membranes manufacturers are preferred, what the advantages are, and how to select the correct Membrane type.

What Are PVDF Hollow Fiber Membranes?

PVDF hollow fiber membranes are one type of ultrafiltration membrane manufacturers that is made of Polyvinylidene Fluoride, which is a high-grade material for chemical durability and filtration. PVDF hollow fiber membranes are manufactured precisely in a hollow and cylindrical form as they provide the largest surface area in the filtration of water and wastewater.

Key Features of PVDF Hollow Fiber Membranes

High Chemical Resistance

Due to the incorporation of PVDF, the coating is also chemically inert and resistant to several chemical solutions, including strong acids, alkalis, and organic solvents. This makes PVDF hollow fiber membranes manufacturers suitable especially for industrial purposes and where the feed water could contain chemicals.

Durability and Strength

PVDF has better mechanical properties such as high strength leading to high-pressure compatibility of the hollow fiber membranes, which is ideal for large-scale filtration. Manufacturers of ultrafiltration membranes tend to focus on the mechanical properties of the membranes since these properties determine the membranes’ reliability and longevity and hence, the need for replacement.

Low Fouling Rates

Fouling, or the accumulation of unwanted material on the surface of the membrane, is a major problem in filtration processes. PVDF hollow fiber membranes manufacturers provoke relatively low fouling, thus its rapid replacement and stable work in time.

High Flux Rate

The feature of the hollow fiber structure enables an increased water flux rate, consequently, more water filtered at a given amount of time. This is particularly important in large-scale productions where the amount of purified water is likely to be a large volume.

Applications of PVDF Hollow Fiber Membranes

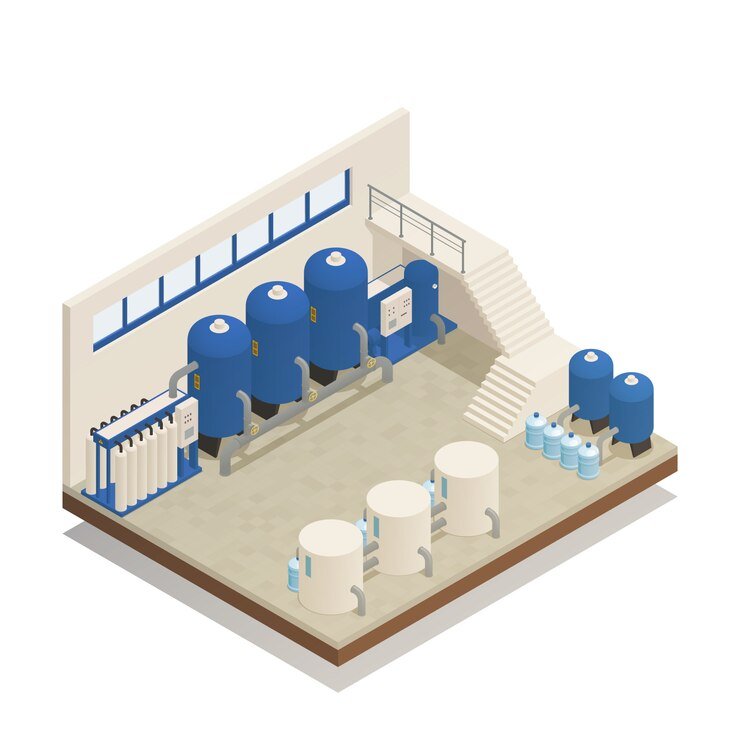

Water and Wastewater Treatment

In water purification processes in city or factory water supplies, the PVDF hollow fiber membranes manufacturers are employed to eliminate bacteria, viruses, or other entities and purify water for drinking or reuse.

Food and Beverage Industry

These membranes are used in the food and confectionery industry to remove any impurities in water they use in their production process to meet some regulatory stipulations.

Pharmaceutical Industry

In the pharma industry, in particular, in the production of medicines, the application of PVDF hollow fiber membranes manufacturers enables to maintenance of a high-quality final product, making water and other liquids pure from interferences.

Why Choose PVDF Hollow Fiber Membranes?

Compared to other materials like PES or other materials PVDF hollow fiber membrane has better chemical stability, tensile strength, and non-d degradation by UV or thermal energy. For projects where chemical exposure, high pressures or temperature may be conditions, PVDF hollow fiber membrane manufacturers provide a more dependable product.

Longer Service Life

PVDF membranes have better durability than many other materials, and thus the frequency of replacement is minimal which in turn affects the amount of time that the equipment is out of order for repairs.

Higher Efficiency

Since the water flux rate is very high and fouling is lower in the PVDF hollow fiber membranes, filtration processes are efficient and faster.

Eco-Friendly

PVDF membranes are in one way considered environmentally friendly since they hardly need replacement often and when this is done it greatly reduces waste. Further, they clarified this reduces fouling thus requiring fewer chemicals to clean them, hence cutting down their effects on the environment.

How to Choose the Right PVDF Hollow Fiber Membrane for Your Project

Selecting the appropriate type of ultrafiltration membrane manufacturers also depends on several factors such as the project conditions and the varieties of contaminants to meet. Here’s a guide to help you make an informed choice:

- Define Your Filtration Needs

When selecting the membrane, it is very important to identify its purpose in your system. Is it used to filter bacteria and viruses or are used primarily for sediment and other larger particles? It will depend on the pore size and the kind of PVDF hollow fiber membrane of contaminants you wish to filter out.

- Consider the Feed Water Quality

There is an agreement that water quality within the system exerts a strong influence on the membrane. If the water is chemically charged, oily, or full, examine whether the membrane has adequate chemical endurance to the contaminants. Well-established ultrafiltration membrane suppliers will advise customers on which type of membrane is most suitable for the feed water.

- Assess Membrane Performance Requirements

When assessing membranes, the flux rate — the volume of water filtered over a certain area at one time – and the rejection rate — the efficiency of the membrane in removing unwanted contaminants — are fundamental parameters. High throughput projects require PVDF hollow fiber membranes with high flux rates as more water can be filtered at one time.

- Choose the Right Pore Size

The efficiency of the pore size in removing contaminants in water can only take certain sizes of contaminants. A PVDF hollow fiber membrane can be grouped by pore sizes which are applicable across different filter levels. Applications that require microfiltration should have a smaller pore size while slightly larger pore sizes will be appropriate for water treatment.

The Importance of Working with Quality Ultrafiltration Membrane Manufacturers

When selecting an ultrafiltration membrane, partnering with a reliable manufacturer is essential. Quality manufacturers like ultrafiltration membrane manufacturers who specialize in PVDF hollow fiber membranes ensure that their products meet stringent industry standards, offer technical support, and guide clients through the selection process.

Why Primem Is the Right Choice

Primem is a trusted provider in the membrane industry, offering high-quality PVDF hollow fiber membranes designed to meet various industrial and commercial needs. With a focus on durability, high-performance features, and customer support, Primem is committed to delivering products that meet the highest filtration standards. By choosing Primem, you can be confident that you’re investing in a PVDF hollow fiber membrane that combines efficiency, reliability, and sustainability for your project.