At Artistic Milliners, innovation is the foundation of our approach to denim manufacturing. For decades, we’ve been committed to producing high-quality denim while embracing cutting-edge technology and sustainable practices. As a globally recognised name in the industry, we strive to blend traditional craftsmanship with advanced manufacturing techniques, ensuring that each piece of denim reflects our commitment to excellence, sustainability, and forward-thinking solutions.

This article offers an in-depth look at the technology and practices that set Artistic Milliners apart. With a focus on quality, efficiency, and environmental responsibility, our methods exemplify what it means to be a leader in the global denim industry.

The Role of Automation in Denim Manufacturing

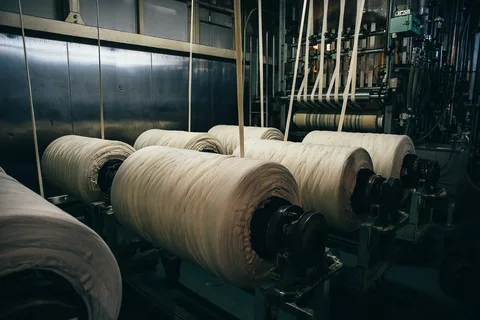

In the fast-evolving world of textile manufacturing, automation has become indispensable. At Artistic Milliners, we have integrated automation at various stages of our production to enhance precision, consistency, and efficiency. From automated cutting machines to robotic arms for fabric handling, we employ technologies that minimise human error and accelerate production time without compromising on quality.

Automation allows us to meet the high demand for denim products globally while ensuring each item meets our exacting standards. By reducing manual labour in specific processes, we not only enhance production efficiency but also create safer working environments for our employees. Additionally, these systems allow us to optimise fabric utilisation, which helps in reducing waste—a vital component of our sustainability initiatives.

Laser Technology for Precision and Sustainability

One of the most notable innovations in our denim manufacturing process is the use of laser technology. Traditional techniques for creating patterns, fading, or whiskering on denim often require large amounts of water and chemicals. However, our state-of-the-art laser technology enables us to achieve these effects with minimal environmental impact.

Laser machines precisely etch patterns onto the denim fabric, reducing the need for water and harmful chemicals. This technology not only helps us reduce our carbon footprint but also provides greater control over the designs, ensuring each garment meets our creative vision. As we continue to refine this technique, we remain committed to providing consumers with high-quality denim that’s crafted responsibly.

Ozone Washes: A Revolutionary Step in Eco-Friendly Finishing

Denim finishing processes, such as washing, have traditionally required significant water usage and chemical treatments. At Artistic Milliners, we employ ozone washing technology, an innovative solution that uses ozone gas to clean and treat denim without the need for harsh chemicals. This process not only conserves water but also reduces energy consumption, making it a greener alternative to conventional washing methods.

Our adoption of ozone washing technology aligns with our sustainability goals by minimising waste and preserving natural resources. As a company dedicated to responsible production, we continuously seek out technologies like ozone washing to ensure our operations reflect our commitment to environmental stewardship.

Water Conservation through Advanced Recycling Systems

Water conservation is a core aspect of our sustainable manufacturing practices. As denim production can be water-intensive, Artistic Milliners has implemented advanced water recycling systems within our facilities. These systems allow us to treat and reuse water, significantly reducing the amount required for production. By reclaiming and recycling water, we not only conserve a valuable resource but also minimise wastewater discharge, which helps protect surrounding ecosystems.

Our commitment to water stewardship doesn’t stop at recycling; we’re also dedicated to adopting waterless or low-water dyeing techniques wherever possible. This comprehensive approach ensures that we meet the highest standards of sustainability while maintaining the superior quality that customers expect from our denim products.

Sustainable Dyeing Techniques: Reducing Chemical Usage

Dyeing is a crucial part of denim production, but traditional dyeing methods can have a considerable environmental impact due to the use of chemicals and excessive water. At Artistic Milliners, we prioritise sustainable dyeing techniques, using environmentally friendly dyes and processes that limit the need for harmful chemicals.

One technique we use is Indigo Dyeing, which is specifically optimised to reduce water usage. Additionally, we work with low-impact dyes that are less harmful to the environment and ensure the health of our workforce. By investing in sustainable dyeing practices, we are able to provide high-quality, richly coloured denim without compromising our responsibility to the planet.

Robotics and Data Analytics for Enhanced Quality Control

Maintaining a consistent level of quality is essential to our brand. To ensure this, we have incorporated robotics and data analytics into our quality control processes. Robotics help in precise fabric inspections, detecting flaws that may not be visible to the human eye. By automating these quality checks, we can uphold the integrity of our products and avoid defects that might otherwise go unnoticed.

Data analytics, meanwhile, plays a crucial role in optimising our production. Through data collection and analysis, we gain insights into production trends, identify areas for improvement, and refine our processes in real time. This use of analytics not only supports quality control but also helps us operate more efficiently, further aligning our operations with our commitment to sustainability.

Embracing Renewable Energy in Denim Production

Energy efficiency is a key factor in sustainable manufacturing. At Artistic Milliners, we are committed to reducing our carbon footprint by harnessing renewable energy sources. Our facilities are equipped with solar panels, enabling us to generate a portion of our electricity from solar power. This transition to renewable energy reduces our dependence on fossil fuels, thus lowering greenhouse gas emissions and furthering our commitment to sustainability.

By integrating renewable energy, we demonstrate our dedication to protecting the environment while also setting an example for other manufacturers. Our approach proves that a shift towards sustainable energy sources is not only possible but also beneficial for long-term operational resilience.

Fostering a Sustainable Workforce

At the heart of Artistic Milliners are our employees, and we believe that a sustainable business is one that respects and values its workforce. We are proud to offer a work environment that promotes health, safety, and equal opportunities. Our training programs ensure that our employees are equipped with the skills they need to operate modern machinery, understand sustainable practices, and contribute to the overall success of the company.

Social responsibility is a fundamental part of our mission, and we are committed to maintaining fair labour practices and promoting diversity within our workforce. By fostering a supportive and inclusive work environment, we build a sustainable foundation for the future growth of Artistic Milliners.

The Future of Denim Manufacturing at Artistic Milliners

As leaders in the global denim industry. we are constantly exploring new ways to innovate and improve our manufacturing techniques. Our commitment to advanced technologies and sustainable practices drives us to continually refine our processes. From laser technology to renewable energy, each step we take reflects our dedication to a responsible future in denim production.

Looking ahead, we are investing in research and development to identify emerging technologies that can further enhance our operations. By staying at the forefront of innovation, we aim to deliver denim products that not only meet but exceed industry standards for quality and sustainability.

Conclusion: Artistic Milliners Leading the Way in Sustainable Denim Manufacturing

Through our advanced manufacturing techniques, Artistic Milliners has redefined what it means to produce denim responsibly. From automation and laser technology to renewable energy and sustainable dyeing, every aspect of our process is designed to minimise environmental impact while ensuring the highest quality. Our dedication to continuous improvement has established us as a trusted name in the global denim industry.

Our journey towards sustainable manufacturing is far from over, and we remain committed to exploring new ways to innovate and protect our planet. By choosing Artistic Milliners, you support a brand that values sustainability, quality, and social responsibility. Together, we can shape a future where denim is produced in harmony with the environment, setting a new standard for excellence in the fashion industry.