A pipe seal is essential in any plumbing, construction, or industrial project. It prevents leaks, keeps materials intact, and protects systems from damage. A pipe seal acts as a barrier, shielding the contents of the pipe from outside elements and ensuring everything within the pipe stays secure.

Effective pipe sealing is crucial for maintaining system integrity, especially under pressure. This guide explores what a pipe seal is, the materials commonly used, and the types of seals available. We’ll also cover various applications of pipe seals and share best practices for creating a durable, waterproof seal. By understanding how pipe seals work and selecting the right type, you can achieve a long-lasting, leak-free system that remains efficient and reliable in demanding conditions.

What Is a Pipe Seal?

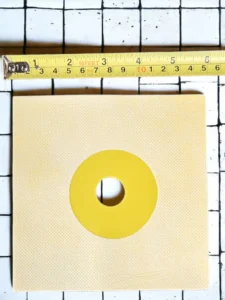

Pipe joint seal available at Cosyspace is a component or material used to create a tight, leak-proof barrier between connected pipes or at pipe endings. It prevents fluids, gasses, or contaminants from escaping or entering the piping system, maintaining the integrity and functionality of the system. Pipe joint seals are essential for plumbing, industrial, and infrastructure applications, where they help to control pressure, protect against leaks, and keep the environment and surrounding structures safe.

Made from materials like rubber, silicone, metal, or composite compounds, pipe seals come in various forms, such as O-rings, gaskets, and threaded seal tapes. Each type is designed to withstand specific pressures, temperatures, and conditions. Ultimately, pipe seals are vital for ensuring system efficiency, longevity, and safety by preventing costly damages and maintaining stable performance.

Why Are Pipe Seals Important?

Plumbing sealant serve several essential functions, including:

- Leak Prevention: They prevent water, gas, or chemical leaks that could damage property or harm the environment.

- Structural Integrity: A proper seal reinforces the pipe structure, reducing wear and tear over time.

- Waterproofing: For pipes in walls, underground, or underwater, seals offer a robust waterproof barrier.

- System Efficiency: By maintaining pressure within the pipe, seals optimize system performance.

Without effective leak prevention, a system becomes vulnerable to leaks, contamination, and even complete failure.

Types of Pipe Joint Seal Materials

Pipe joint seals can be crafted from various materials, each with unique benefits. Choosing the right material for the job ensures durability and leak protection.

1. Rubber Seals

Rubber is widely used in pipe fitting seal due to its flexibility and resilience. Rubber seals withstand high pressures and temperatures, making them ideal for plumbing, wastewater systems, and gas pipelines.

2. Silicone Seals

Silicone seals are favored in high-temperature applications. They offer excellent flexibility and can resist extreme temperatures, making them suitable for industrial applications and hot water pipes.

3. Metal Seals

Metal seals are durable and often used in high-pressure or corrosive environments. They are commonly found in oil and gas industries, where high durability is essential.

4. Polyurethane Seals

Polyurethane seals are highly resilient and resistant to wear and tear. They work well in environments where movement and stress are factors, such as dynamic pipes or joints in large structures.

Common Types of Pipe Seals

Plumbing sealants come in various forms to suit different applications. Here are some of the most common types:

1. O-Ring

O-rings are among the simplest and most widely used seals. These rings of rubber or silicone create a watertight seal by compressing between two pipe surfaces. They’re versatile and can be used in water pipes, gas pipes, and hydraulic systems.

2. Gaskets

Gaskets are flat seals placed between two surfaces to prevent leaks. Gaskets are often used in plumbing, machinery, and automotive applications.

3. Compression Seals

Compression seals work by squeezing the seal material to create a tight barrier. These seals are used in applications with fluctuating pressures, such as HVAC systems or pipelines.

4. Lip Seals

Lip seals feature a flexible lip that presses against the pipe wall, creating a tight seal. They’re often found in moving systems where there’s a need for low-friction, high-efficiency sealing.

5. Thread Seal Tape (Teflon Tape)

Thread seal tape, often known as Teflon tape, is used to seal pipe threads in plumbing applications. It provides a strong, waterproof seal that prevents leaks and corrosion.

Applications of Pipe Seals

Plumbing sealants are essential in various sectors, and each has unique demands on the seals used:

1. Plumbing

In residential and commercial plumbing, plumbing sealant keeps water systems leak-free. They prevent water from escaping pipes, which is essential for maintaining efficiency and avoiding water damage.

2. Industrial and Chemical Processing

Industrial applications involve high pressures, temperatures, and sometimes corrosive materials. Here, pipe fitting seals ensure containment of fluids and gasses, preserving safety and system performance.

3. Gas and Oil

In the gas and oil industries, pipe joint seals withstand extreme pressures and resist corrosion. They are vital for safe transport and prevent leaks in pipelines that carry dangerous or flammable substances.

4. HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems require reliable seals to maintain air pressure and regulate temperatures efficiently. Plumbing sealants here ensure that air moves through the ducts without leaking.

5. Infrastructure and Civil Engineering

In large-scale infrastructure projects like tunnels, dams, or underground pipelines, seals provide waterproofing and support structural stability.

Key Benefits of Pipe Sealing for Waterproofing

Effective pipe fitting seal offers numerous benefits, especially in terms of waterproofing:

- Leak Prevention: A good pipe joint seal stops leaks at their source, protecting nearby structures from water damage.

- Longer Lifespan: Seals reduce the strain on pipes, protecting against wear and tear.

- Corrosion Protection: Many seals prevent moisture and other substances from causing corrosion.

- Cost Efficiency: Leak precautions reduce maintenance needs and extend the lifespan of a system, saving costs in the long term.

How to Choose the Right Pipe Seal

Selecting the right leak prevention depends on factors like application, material compatibility, temperature range, and pressure requirements. Here’s what to consider:

- Type of Pipe and Material Compatibility

- Choose a seal material that’s compatible with the pipe material. For example, rubber seals may work well with PVC pipes, while metal seals are suitable for steel pipes.

- Temperature and Pressure Range

- Ensure the seal material can withstand the maximum operating temperature and pressure of the system. High-temperature applications may require silicone or metal seals.

- Chemical Resistance

- In industrial or chemical environments, select seals that resist the chemicals involved.

- Movement and Flexibility

- For pipes that move or flex, choose a flexible seal, such as rubber or silicone, to accommodate movement without breaking the seal.

Steps to Achieve a Long-Lasting Pipe Seal

Following proper installation and maintenance practices is essential for a lasting pipe joint seal. Here’s a quick step-by-step guide:

1. Clean the Surface

Ensure both pipe surfaces are clean and free from debris, rust, or old sealant. This improves adhesion and seal effectiveness.

2. Apply the Sealant or Install the Seal

Apply the chosen sealant, gasket, or O-ring to the connection point. Make sure it’s positioned correctly to avoid gaps or misalignment.

3. Tighten Properly

For threaded or compression seals, tighten the connection carefully. Avoid over-tightening, as it can damage the seal.

4. Inspect for Leaks

Once the seal is in place, test the system for leaks. This can be done with water, air, or other fluids depending on the application.

5. Regular Maintenance

Regularly inspect the seal over time, especially in high-pressure or industrial settings, to check for wear and tear.

Tips for Waterproofing with Pipe Seals

- Use the Right Sealant: For waterproofing, choose a sealant that’s designed for water exposure. Silicone-based and rubber seals are often waterproof.

- Apply Sealant Evenly: Make sure sealant covers all gaps evenly to prevent leaks.

- Check Pressure Ratings: Ensure that the seal can withstand the system’s pressure to maintain a strong waterproof barrier.

- Choose Corrosion-Resistant Materials: In water-based environments, use seals resistant to corrosion for longevity.

Common Pipe Seal Problems and Solutions

Even with the best practices, pipe waterproofing may encounter issues over time. Here’s a look at common problems and how to address them:

- Leakage Due to Misalignment

- Solution: Ensure the pipe and seal are properly aligned during installation.

- Seal Degradation from Chemical Exposure

- Solution: Use seals made from chemically resistant materials if handling harsh chemicals.

- High-Temperature Damage

- Solution: Use temperature-resistant seals like silicone for high-temperature applications.

- Wear and Tear in Moving Pipes

- Solution: Install flexible seals that can handle movement without damage.

- Corrosion Around the Seal

- Solution: Use corrosion-resistant materials, especially in plumbing or HVAC systems.

Innovations in Pipe Sealing Technology

New materials and technologies have transformed leak prevention. Modern pipe joint seals are more durable, resistant to extreme conditions, and environmentally friendly. Key innovations include:

- Liquid Silicone Seals: Improved flexibility and resistance to high temperatures.

- Composite Gaskets: Made from layered materials for multi-functional use.

- Advanced Rubber Compounds: Highly durable and resistant to chemicals and abrasion.

Conclusion

A leak prevention may be small, but it’s essential for waterproofing and creating a durable, leak-free system. Choosing the right materials, installing them properly, and regular maintenance ensure lasting performance. Pipe joint seals stop leaks, protect the system, and improve efficiency. In residential plumbing, industrial pipelines, or large infrastructure, a good seal keeps everything secure and running smoothly.

Effective pipe waterproofing is key to preventing costly damage, preserving structural integrity, and maintaining safety. For any project involving pipes, a reliable seal is critical. It provides the barrier needed to keep fluids or gases contained, protect the environment, and ensure operational stability. Investing in quality pipe joint seals and proper installation goes a long way in preventing issues and extending the life of your systems.